by George Bulliss

Sometimes the simple things can get overlooked as we set up and run our jobs on the mill. Take the lowly vise jaw for example. The standard-sized jaws that come with the vise will serve for the majority of jobs that the mill is likely to tackle. Coupled with a set of thin parallels, a wide variety of work sizes can be held with good results.

Difficulties can arise however when the workpieces extend past the standard jaw length. There can also be problems with the parallels when running multiple pieces. It doesn’t take much for a stray chip to work its way under the parallel, causing a change in the workpiece height. Unfortunately, this change often is not noticed until after the cycle start button is pushed.

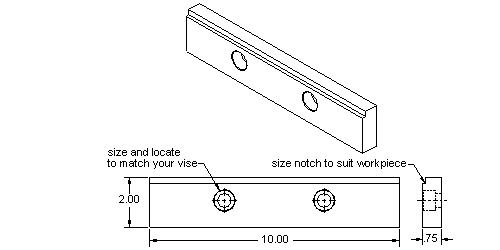

One way to avoid these problems is to have a variety of custom jaws on hand. The time spent on making a few jaws will pay for itself quickly, especially if multiple parts are being milled. The accompanying drawing shows one example of a custom jaw. Every shop will have different needs and the design of the jaws should reflect your work and equipment.

When using jaws similar to the one shown, I give them a tap with a soft-faced hammer after attaching them to the vise, to make sure they will not shift down during the job. I then re-cut the notch, skimming just enough to clean up the jaw. This assures that the tram of the jaws will be perfect and that the part will sit parallel to the table.

I know that sometimes the rush to just get the job done makes it difficult to find the time to work on shop tooling. If you can find the slow time though, make up a few specialty jaws. Once you have them on hand, you will wonder what you ever did without them.

Please do us a tremendous favor and forward this e-mail on to your machining friends!

Are you not a subscriber to DIGITAL MACHINIST? Visit us at www.digitalmachinist.net and request a no-obligation issue, or call and request it at 1-800-447-7367. Tell them you received an e-mail from a friend!

And don’t forget to check out Digital Machinist’s page on Facebook and our Twitter feed!

Your friend thinks you’ll enjoy DM, or you wouldn’t have this e-mail!

We hope you enjoyed this e-mail tip, brought to you by your friends at Digital Machinist.

Get Involved!

Do you enjoy our e-mail tips? Has one of them ever “knocked something loose” in your head? Your tip could be a future e-mail blast from your favorite magazine. Just send your tips to george.bulliss@VPDemandCreation.com. If we use your tip, we will extend your subscription by an issue. We like to see 200 to 300 words, plus an image, if available. Thanks!

We hope you enjoyed this e-mail tip, brought to you by your friends at Digital Machinist, dedicated to precision metalworking.