Joerg Hugel

I have enjoyed the email tips and have been able to make use of several of them. I recently looked at my pull-out collars that I use on the lathe and mill and thought maybe your readers would be interested in how I remove tools with tapered shafts from the spindle.

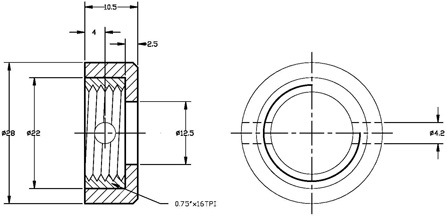

For my lathe and mill, I’ve made two collars from brass, as seen in the photo and drawing. To allow the internal thread to run to full depth, the collar is built up from two parts fit together with Loctite. Finally, the 4.2mm holes were drilled. I am located in Switzerland, but perhaps in other countries nuts are available to fit the Sherline’s spindle nose. This would greatly simplify the construction.

In use, the taper is removed by loosening the drawbar, about one turn, and then no hammer is applied. The collar is turned off from the headstock spindle with the assistance of two tommy bars, also seen in the photo. Adding knurled brass handles to the bars was a tip from a friend. I hope this tip helps someone out!

Thanks Joerg, your subscription has been extended by an issue!

Please do us a tremendous favor and forward this e-mail on to your machining friends!

Are you not a subscriber to DIGITAL MACHINIST? Visit us at www.digitalmachinist.net and request a no-obligation issue, or call and request it at 1-800-447-7367. Tell them you received an e-mail from a friend!

And don’t forget to check out Digital Machinist’s page on Facebook and our Twitter feed!

Your friend thinks you’ll enjoy DM, or you wouldn’t have this e-mail!

We hope you enjoyed this e-mail tip, brought to you by your friends at Digital Machinist.

Get Involved!

Do you enjoy our e-mail tips? Has one of them ever “knocked something loose” in your head? Your tip could be a future e-mail blast from your favorite magazine. Just send your tips to george.bulliss@VPDemandCreation.com. If we use your tip, we will extend your subscription by an issue. We like to see 200 to 300 words, plus an image, if available. Thanks!

We hope you enjoyed this e-mail tip, brought to you by your friends at Digital Machinist, dedicated to precision metalworking.